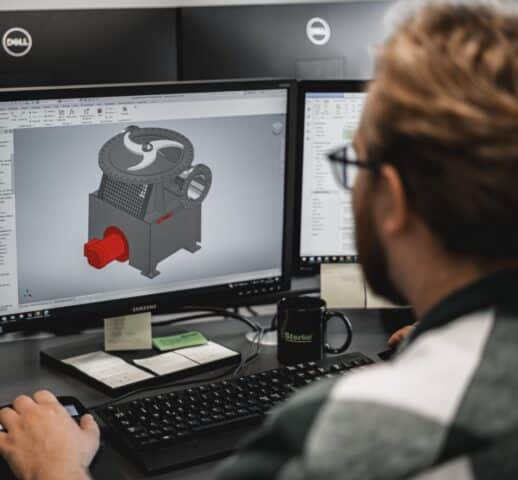

Innovation and Design

Our team of experienced engineers is ready to develop and design solutions that can best meet your needs. We can be involved from the initial idea development to designing and creating the finished production basis, always keeping production in mind throughout the phase. This ensures that the drawings can be efficiently translated into reality in production. We design steel structures, machinery, production and lifting equipment, and much more. Additionally, we work with all types of materials, including black steel, aluminum, and stainless steel.

FEM – Your Guarantee for Strong Solutions

At Sterke, we deliver strong products and solutions that we optimise using the Finite Element Method (FEM). With FEM, we can optimise processes related to material selection, material consumption, weight, and strength, both for individual components and complete structures. This method is effective in reducing costs in product development, and we also use it to analyse geometrically complex structures and components. Moreover, it allows us to calculate various different problems and combinations thereof. At Sterke, we perform FEM calculations across various industries, including offshore, wind, and industrial sectors.

Documentation and certifications

In our R&D department, we handle everything from documentation tasks, where we have the expertise to perform CE marking of products, to large design development projects. One of our strong characteristics is our adaptability, and this applies especially to our R&D department. No task is the same, and we specialise in understanding our customers’ wishes and needs. We create both custom-designed solutions, adapt customers’ existing drawings, and can also manage the entire process related to RAMS (Risk Assessment Method Statement). Sterke is, in other words, your guarantee of a well-executed piece of work.

Our competent engineers are ready to assist if you have a challenge that requires new development. We can design and draw machines tailored to your needs, and we also have the expertise and facilities in-house to produce them.

We turn your idea into reality. At Sterke, our experienced engineers are ready to take your idea and, in close collaboration with you, prepare it for production. We tailor the solution to your needs and desires, and our modern production facilities also make it possible to manufacture it with us.

At Sterke, we can also assist if you already have a finished drawing – either from us or elsewhere. We prepare the production basis, and then we cut, build, weld, and assemble the solution. We conduct complete tests according to applicable SAT and FAT procedures, and we always provide complete documentation, including CE marking.

At Sterke, we aim to be the best partner for you as a customer, and therefore, professional advice and innovation are central keywords for us. We can accompany you throughout the journey, starting from the ideation phase, where our experienced engineers draw and design based on your wishes and needs, all the way to production and finished assembly. All of this is to provide you with the best service throughout the process.

Read more about SterkeAll installations are, of course, carried out according to applicable SAT and FAT procedures, and we always provide comprehensive documentation. At Sterke, we also prepare test reports and other relevant documents, and the equipment is CE-marked in accordance with current legislation. In connection with the mandatory inspections, we also offer to keep track of Technical Control Inspections, allowing you to focus on your company’s core tasks.

Our engineers are accustomed to assisting our customers with projects and have extensive knowledge of materials, processes, and production optimisation within steel and hydraulic solutions. They have considerable experience in understanding the challenges inherent in tasks and are often involved very early in the development phase, from production to final assembly and testing at the customer’s site.

– Kim Palsgaard Thomsen, Director COO Engineering & Service at Sterke

As your professional partner, we value not only the design and production phases but also the importance of subsequent maintenance of your components and machinery. Therefore, we are always ready to handle both spontaneous repairs and planned maintenance tasks according to your needs.

Our competent team is ready to assist you with your task or project, so don’t hesitate to contact us today.

We are the helping hand you need – we are Sterke.

Department manager

Kaj Hosbond Svenningsen

VAT: 33163665

Langerak 8, 9220 Aalborg

Direktør / COO R&D og Aftersales

Kim Palsgaard Thomsen

VAT: 33163665

Langerak 8, 9220 Aalborg

"*" indicates required fields